High-tech PR win: inside OSARO's robotic depalletization system launch campaign

Project overview

Launching a new robotics solution is always a challenge. It's highly technical and can be difficult to translate for a general audience. That's why OSARO partnered with ZingPR to craft a compelling media strategy for its new depalletizing robot. Instead of focusing on specs, we highlighted the real-world benefits: warehouse safety and efficiency.

To demonstrate market momentum, we timed the launch of the OSARO Robotic Depalletization System to precede two ‘design wins’ that reflected the immediate adoption of the system by key partners. To maximize the impact of the news, the announcements were made leading up to, and during, the MODEX trade show

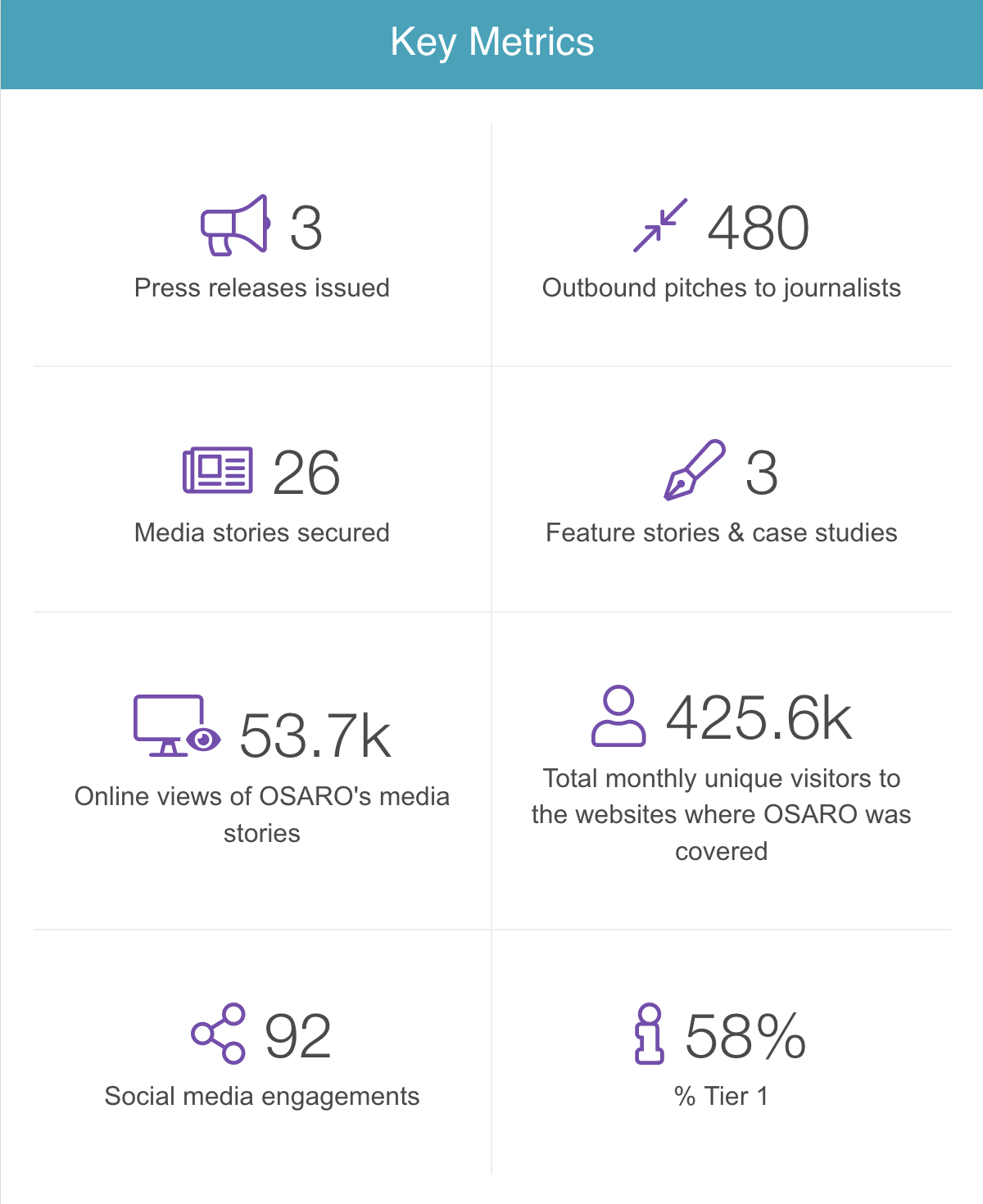

Ahead of each announcement, dozens of personalized media pitches were sent to OSARO's target journalists, optimized for the specific interests and needs of those journalists. This resulted in:

26 stories placed in predominantly Tier 1 publications

these stories were viewed by an estimated 54K readers at these publications

the total monthly reach of these publications is 426K readers

Telling the OSARO story

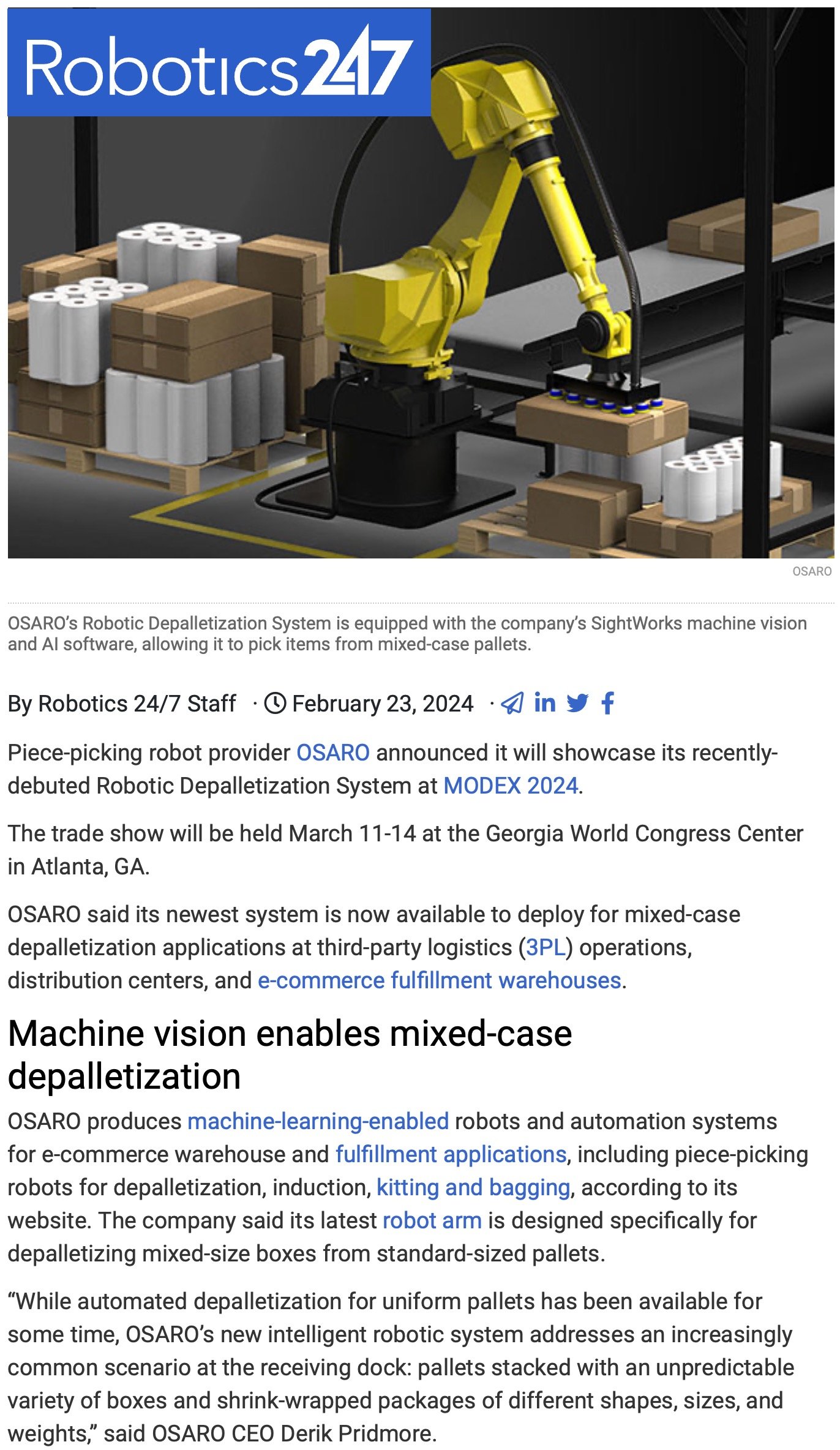

Busy warehouses are a gruelling environment for human workers, especially where in-bound goods arrive. While many of the tasks downstream from the loading dock have been automated, the hazardous manual tasks of unstacking, sorting, scanning, opening, and transferring (decanting) master pack box contents into standard totes are often still performed by humans.

Goods typically are shipped on pallets. Stacked high on pallets, boxes and cases of mixed goods pose serious injury risks because of their size, weight, handling procedures, and potential for structural failure. The important task of quickly unloading (or, depalletizing) them as they arrive on the loading dock is slow, hard work that can be dangerous and cause damage to fragile contents.

In February 2024, OSARO announced the OSARO Robotic Depalletization System. Equipped with OSARO SightWorks™ Perception Software, this new robotic solution from OSARO can recognize, select and successfully grasp the varied sizes and materials of unevenly stacked packages commonly found on mixed-case pallets that arrive at a loading dock.

New robot quickly finds employment

Since its launch, the OSARO Robotic Depalletization System has already been put to work — this time, helping other robots.

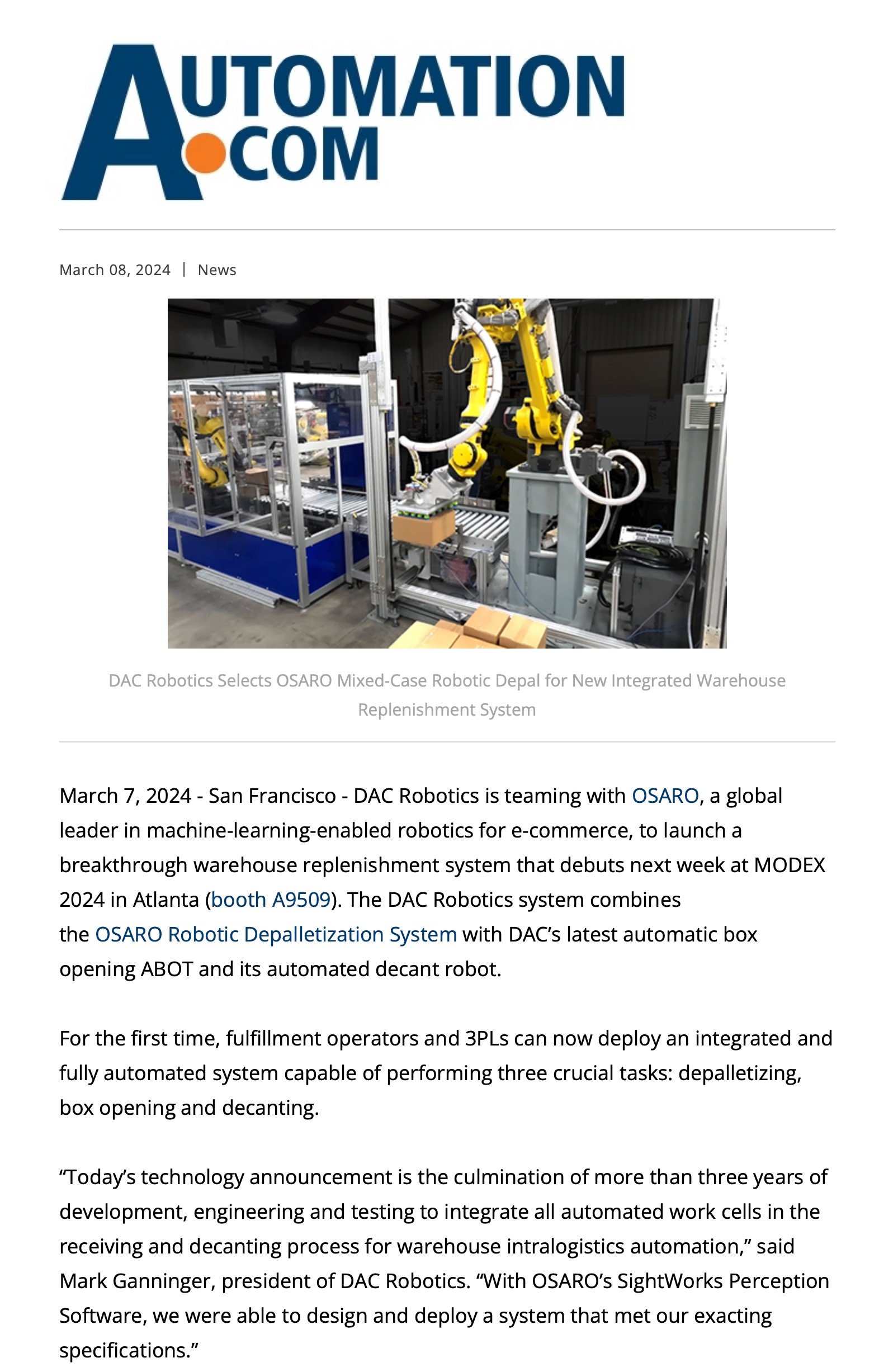

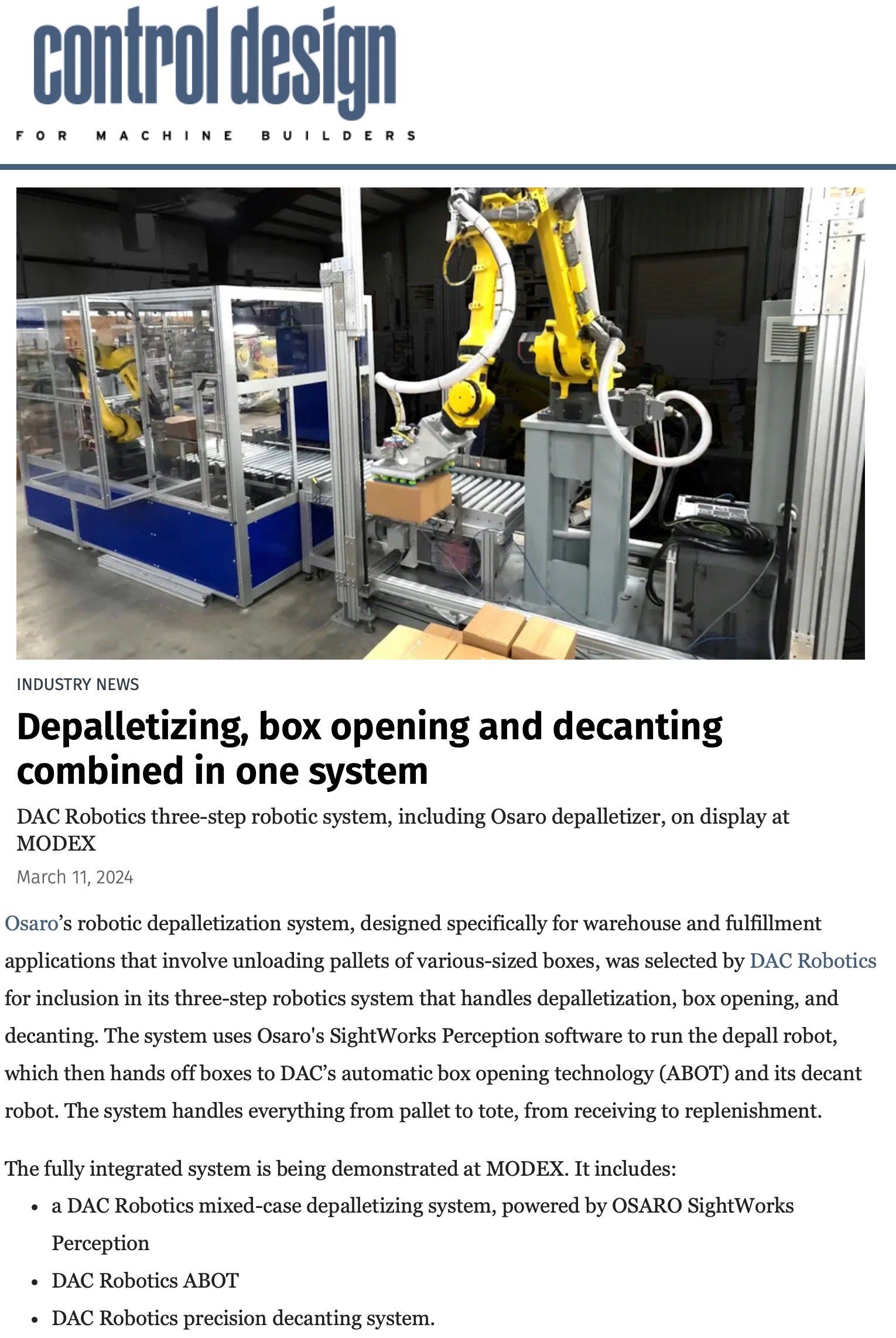

First, as an integral component of a multi-robot system offered by DAC Robotics. Here, OSARO fulfills a crucial front-end role for DAC Robotics’ fully automated inventory replenishment system, which completely automates the handling of dangerous depalletization, box opening, and decanting.

“Today’s technology announcement is the culmination of more than three years of development, engineering and testing to integrate all automated work cells in the receiving and decanting process for warehouse intralogistics automation. With OSARO’s SightWorks Perception Software, we were able to design and deploy a system that met our exacting specifications.”

Video: from pallet to warehouse

Landing in Japan

To reinforce the market success of the system, a separate announcement was made with IHI Logistics & Machinery Corporation (IHI), a Tokyo-based integrator of factory automation equipment and industrial machinery. IHI has licensed multiple OSARO® Robotic Depalletizing Systems for picking, mixed-case depalletizing, induction, kitting, and other automated functions.

PR campaign: widespread Tier 1 coverage

Over several weeks, ZingPR liaised with journalists from various business, trade, and local media outlets to secure a multitude of on-target stories regarding these announcements.

Need PR for your robotics company?

See how we got OSARO featured in Automation World, Robotics 24/7, and more. Contact ZingPR today.